Low Voltage Switchgear

A soft start panel—often referred to as a soft starter or soft start device—is an advanced electrical control solution that gradually increases the voltage supplied to an electric motor during start-up. This controlled acceleration reduces both mechanical and electrical stress, ensuring smoother operation and greater protection for motors, especially when dealing with large or high-inertia loads. By integrating soft start technology, businesses can extend equipment lifespan, lower maintenance costs, and improve overall system reliability.

Choose our high-performance soft start panels to achieve safer, smarter, and more efficient motor control. Get in touch today to find the right solution for your operation.

Overview

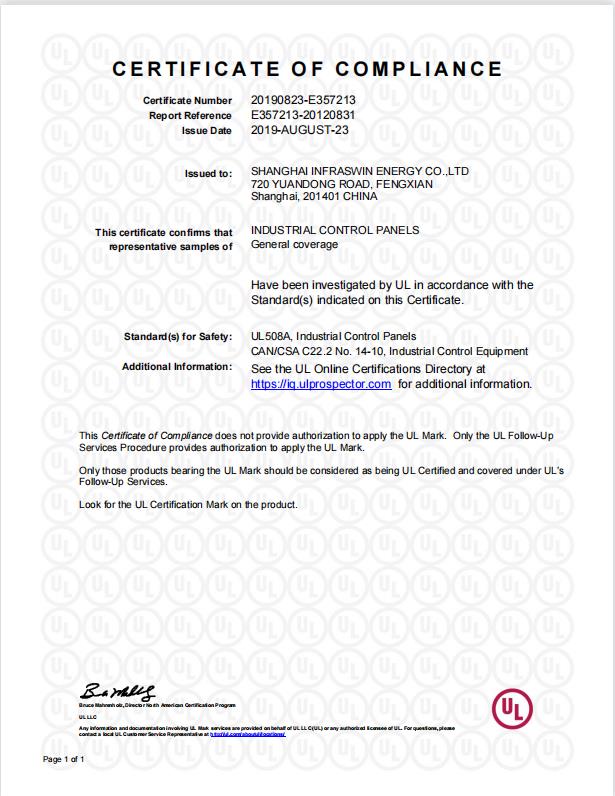

Applicable standards

UL 508A

IEC61000-4 《Amendment 1-Electromagnetic compatibility(EMC)》

Product Overview

What is Soft Start?

Soft start refers to the method of gradually ramping up the voltage and current supplied to an electric motor. Instead of subjecting the motor and connected load to sudden torque and high current, the soft start process ensures a smooth and controlled acceleration.

This technique protects both the motor and the power grid by reducing electrical stress, lowering mechanical wear, and avoiding sudden pressure surges in fluid-handling systems such as pumps and compressors. For example, pumps benefit from avoiding water hammer, while compressors are protected from liquid hammer and excessive mechanical strain.

Difference Between Soft Starter and VFD (Variable Frequency Drive)

While both soft starters and VFDs are used to control motors, they serve different purposes:

Soft Starter

Controls motor starting and stopping.

Limits inrush current and torque shock.

Provides a cost-effective solution when speed control is not required.

Variable Frequency Drive (VFD)

Controls both motor speed and torque by adjusting frequency and voltage.

Enables energy savings, especially in variable-load applications like fans and pumps.

More complex and expensive than soft starters.

In short, a soft starter is best suited for applications where smooth starting and stopping are the main requirements, whereas a VFD is necessary when speed variation and energy efficiency are priorities.

How Does a Soft Start Work?

A soft starter typically uses thyristors (SCRs) or other semiconductor switches to control the voltage supplied to the motor. At startup, the soft starter allows the motor to receive only a fraction of the full voltage, and then gradually increases it until the motor reaches full speed.

Once the motor is running, a bypass contactor may be engaged to reduce heat losses and improve efficiency. During stopping, a soft starter can also provide a soft stop, preventing abrupt halts that could cause hydraulic shocks in pumps or mechanical strain in compressors.

Applications in Motors, Pumps, and Compressors

Compressors

Compressors experience high torque demand during startup, which can cause mechanical stress and damage. A soft starter ensures smooth acceleration, prevents liquid hammer, and extends compressor life.

Pumps

Pumps are prone to a phenomenon known as water hammer—a sudden surge of pressure caused by abrupt starting or stopping. Soft starters eliminate this issue by gradually ramping up and down the motor speed, ensuring a steady fluid flow.

Motors (General)

In general industrial applications, soft starters extend motor lifespan, reduce maintenance costs, and minimize disturbances to the power grid. They are particularly beneficial in large motors where high inrush current could otherwise destabilize the supply network.

Keep in Touch

Company Profile

In 2002, Mr. Zhu Ning, the founder, started his business in China. In 2009, Shanghai Infraswin Energy Co., Ltd. was established. Infraswin is China Soft Start Panel suppliers and OEM/ODM Soft Start Panel company, a high-tech enterprise with 37 patents, integrating R&D, design, manufacturing, and sales. Our company was successfully listed on the National Equities Exchange and Quotations (NEEQ) in 2017. The stock is abbreviated as Infraswin Energy, with the stock code 871504.

Infraswin specializes in intelligent power distribution, as well as comprehensive energy management and automation control equipment integration.

Infraswin is situated at No. 720, Yuandong Road, Fengxian District, Shanghai. Our power distribution and automation control equipment have received CE and UL certifications and comply with China's Guobiao (GB) national standards.

Our main customers include prominent global companies such as Rittal (Germany), Rockwell (United States), Siemens (Germany), ABB (Switzerland), Panasonic (Japan), and GEA (Germany). Additionally, we are proud to be the main supplier of electrical equipment for Shanghai DISNEYLAND as an Original Equipment Manufacturer (OEM).

Factory area(㎡)

Founded in

Project cases

Employees

News Center

Industry News

Frequency Drive Motor Control: VFD Setup, Tuning & Savings2026-02-06

Industry News

NEMA Certified: What It Means, How to Verify, and What to Buy2026-01-30

Industry News

Preventing Electrical Fires and Downtime: An In-Depth Analysis of UL891 Low Voltage Switchgear Safety Design2026-01-29