2025-08-15

Low voltage switchgear plays a pivotal role in the backbone of industrial automation and control systems. As industries become more reliant on automation, ensuring the safe and efficient operation of electrical systems is more critical than ever. Low voltage switchgear provides essential functions that protect and control electrical circuits, which is especially important in environments that demand constant performance and minimal downtime. From manufacturing plants to energy distribution systems, these devices are vital for managing electrical power reliably.

At its core, low voltage switchgear is designed to handle electrical currents within a specific range, typically from 1 kV to 36 kV. It serves as a safeguard, ensuring that if there is any overload, short-circuit, or fault in the system, the affected circuit can be quickly isolated to prevent further damage. In an industrial setting, where heavy machinery and automated processes are at play, such protection is not only crucial for the equipment but also for the safety of personnel working around high-voltage systems. Without the right switchgear, the risk of costly interruptions or even accidents increases significantly.

One of the key benefits of integrating low voltage switchgear into industrial automation is its ability to offer reliable control. These devices act as a critical interface between the power supply and automated systems, ensuring that electrical energy is distributed correctly to various parts of a production line or facility. For industries relying on precision and continuous operation, such as automotive manufacturing or chemical processing, the quality and reliability of switchgear directly impact production efficiency and safety.

Switchgear’s role extends beyond just protection and control. As automation systems become more sophisticated, especially with the rise of smart factories, low voltage switchgear now includes advanced features like digital metering, remote diagnostics, and integration with industrial IoT (Internet of Things). These features enable operators to monitor systems in real-time, identifying potential issues before they cause failures. This proactive approach not only prevents downtime but also optimizes maintenance schedules, ensuring that costly disruptions are avoided.

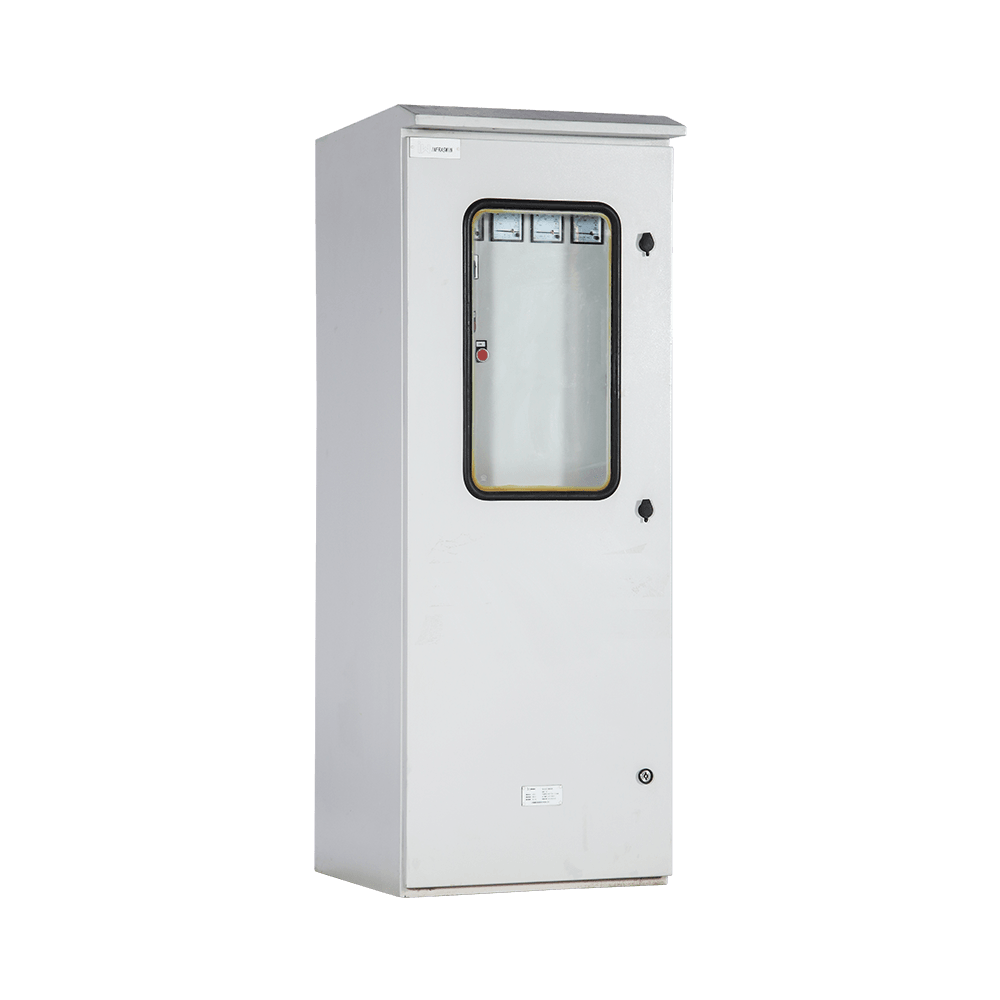

The demand for greater flexibility in industrial automation has also driven innovation in low voltage switchgear design. Modern switchgear is more modular than ever, allowing for customization to meet specific application needs. Whether it's for smaller, low-power systems or large, high-demand environments, low voltage switchgear can be tailored to fit. This adaptability means that industries can scale their operations without compromising on safety or performance.

In industries where space is at a premium, compact low voltage switchgear systems offer significant advantages. For example, in oil and gas installations, where equipment must withstand harsh environments and limited space, compact and reliable switchgear is essential for keeping everything running smoothly. Manufacturers are continuously improving designs to make switchgear more space-efficient, without sacrificing the integrity of the system's performance.

Furthermore, low voltage switchgear is crucial for controlling and isolating power sources in the event of faults or irregularities. Automated processes depend on a constant, stable supply of electrical power to maintain operation. Any disruption can result in delays, faulty products, or even damage to expensive machinery. The rapid fault isolation provided by modern switchgear prevents these issues, helping to maintain both safety and productivity in industrial environments. The role of switchgear in preventing cascading failures within electrical systems is vital, especially when dealing with complex, interconnected processes.

As industries continue to evolve, the integration of low voltage switchgear into industrial automation and control systems remains indispensable. With the right equipment, companies can ensure that their automated processes are safe, efficient, and sustainable. The future of industrial automation will rely heavily on continued advancements in switchgear technology, as it becomes an even more integral component in achieving optimal performance. Whether it's for reducing operational costs, preventing downtime, or maintaining safety, the importance of choosing the right low voltage switchgear cannot be overstated.

For businesses looking to upgrade or integrate new automation systems, selecting high-quality low voltage switchgear is essential. With a wide range of customization options and cutting-edge features, this equipment offers both the reliability and flexibility required for demanding industrial applications. When it comes to keeping your systems running smoothly and efficiently, the right switchgear can make all the difference.