Key Differences and Application Scenarios of UL 891 and UL 508A

In the design of industrial and commercial power distribution systems, correctly understanding and applying Underwriters Laboratories (UL) standards is fundamental to ensuring electrical safety and compliance. Among these, UL 891 and UL 508A are two frequently referenced yet distinct standards with different application scopes.

UL 891: Focus on Low-Voltage Distribution Panels (Switchboards)

- Scope of Application: Suitable for low-voltage AC power distribution centers, switchboards, and service equipment with rated voltages not exceeding 600V.

- Core Requirements: Emphasizes safety protection capabilities under fault conditions, including structural strength, short-circuit withstand strength (e.g., busbar support), temperature rise limits, dielectric testing, and explicit requirements for integrated overcurrent protection.

- Typical Applications: Main distribution panels in buildings, power supply incoming sections of motor control centers (MCCs), data center power distribution units (PDUs), etc.

UL 508A: Focus on Industrial Control Panels

- Scope of Application: Covers the assembly and manufacturing of industrial control panels used in industrial machinery and equipment.

- Core Requirements: Focuses on the safe assembly of control circuits, including component selection, wiring standards, spacing (electrical clearance and creepage distance), matching of protective devices (e.g., circuit breakers, relays), and labeling.

- Typical Applications: Automated production line control panels, pump station control panels, HVAC system control panels, etc.

- Simple Distinction: It can be understood that UL 891 governs "power distribution", while UL 508A governs "control functions". In a complex motor control center (MCC), the main incoming busbar section may need to comply with UL 891, while the individual motor control units containing contactors and PLCs must comply with UL 508A.

The Engineering Philosophy Behind the Standards: Safety, Reliability, and Maintainability

These two major standards are not merely "exams" for market access; they embody profound engineering value:

- Preset Safety Boundaries: Through rigorous type tests (e.g., short-circuit, temperature rise), extreme conditions are simulated to ensure products can handle unexpected situations throughout their lifecycle.

- Standardized Design and Installation: Unified rules for conductor handling, grounding, and labeling significantly reduce on-site installation error rates, enhancing system consistency and maintainability.

- Clear Definition of Responsibility: Using UL Listed or Recognized components and assembling them in compliance with the standards clarifies the responsibility boundaries between manufacturers and integrators, protecting the interests of all parties.

Recommendations for Engineers on Selection and Verification

When addressing specific projects, we recommend the following:

- Clarify Requirements: First, determine whether the equipment is primarily for power distribution, control, or both, to preliminarily identify the governing standard.

- Verify Certification: Request the UL Listing Page from suppliers to confirm compliance with specific standards (e.g., UL 891 or UL 508A).

- Pay Attention to Details: For integrated systems, do not only examine the cabinet certification. Also ensure that internal critical components (e.g., circuit breakers, PLC power supplies) use UL Recognized components and that the assembly process complies with the standards.

- Choose the Right Partner: Prioritize suppliers like Shanghai Infraswin Energy Co., Ltd., which possess in-depth understanding of standards, independent R&D capabilities for products, and extensive system integration experience. We can not only provide compliant products but also engage from the front-end design stage to help optimize the overall solution and mitigate potential technical and compliance risks.

About Shanghai Infraswin Energy Co., Ltd.

The company is dedicated to the R&D, manufacturing, and technical services of intelligent power distribution, power quality management, and energy management systems. We offer a comprehensive product line, covering complete solutions from low-voltage switchgear and control panels to intelligent monitoring systems.

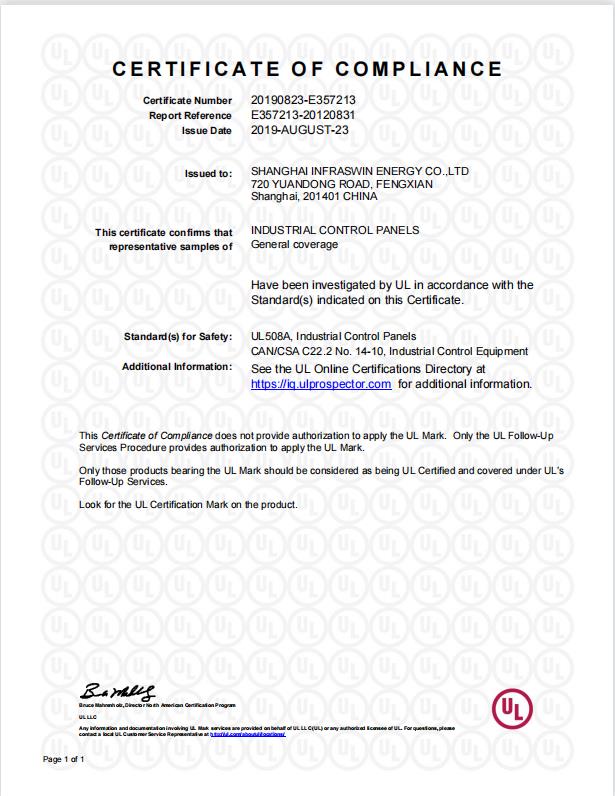

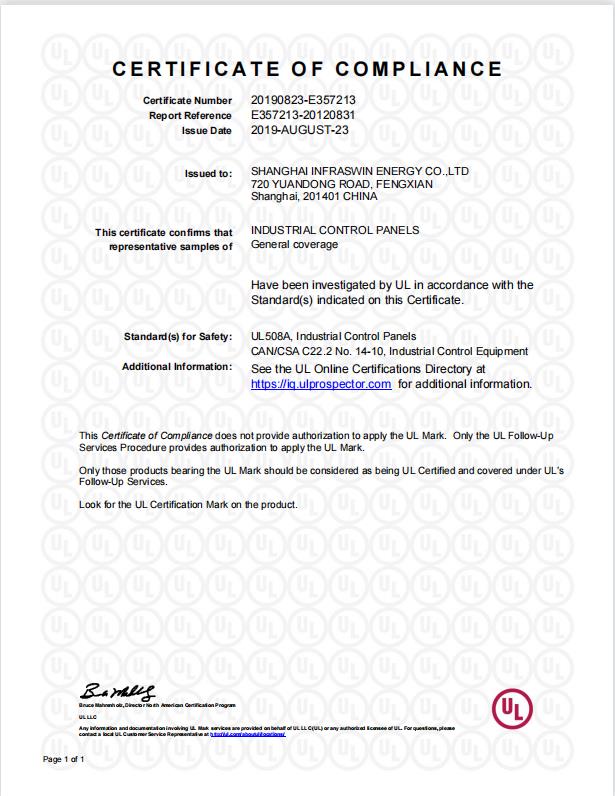

Our core products are certified by UL and other internationally recognized authorities.

The technical team at Infraswin Energy consists of experienced electrical engineers committed to translating rigorous standard requirements into safer, more efficient, and more sustainable value for our customers.