2025-08-29

"AC on, electricity bill soaring?"

For large facilities like shopping malls, hospitals, and data centers, cooling rooms are the real "energy guzzlers." How can we make them more efficient and costeffective? Today, let’s break down the secrets of highefficiency cooling rooms in design, construction, and operation—and see how AI technology helps slash energy costs!

ⅠDesign: Building Efficiency Like Lego Blocks

A highefficiency cooling room isn’t just a pile of equipment—it’s a tailored energysaving solution for specific needs.

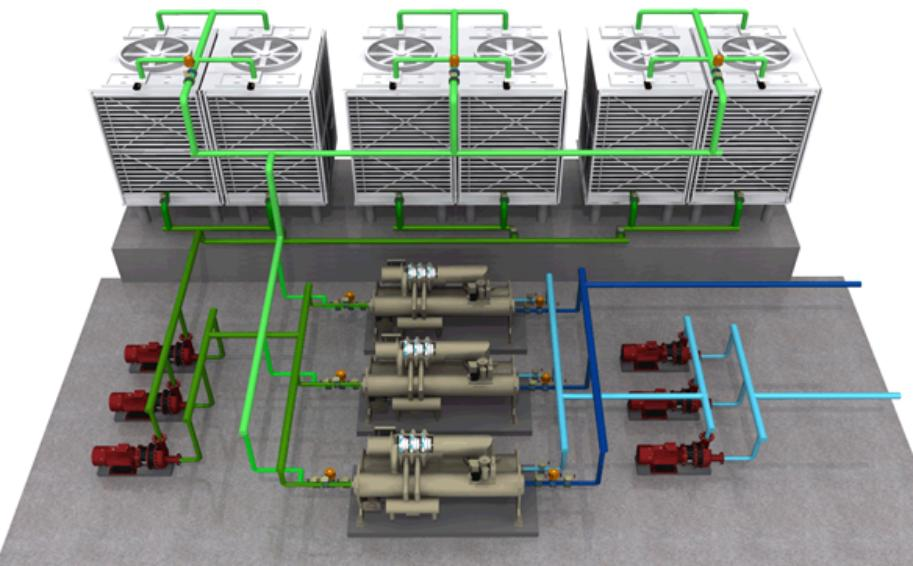

The "Dream Team" of Equipment

Chillers, pumps, and cooling towers must work in harmony, like a wellcoordinated sports team. A mismatched setup (e.g., oversized chillers with undersized pumps) is like asking Yao Ming to ride a kid’s bike—wasteful and ineffective. Today, variablefrequency magnetic levitation chillers, pumps, and cooling towers are gamechangers, automatically adjusting output to save over 30% in electricity costs.

AI Group Control: The "Smart Brain"

Traditional cooling rooms rely on manual adjustments, which are timeconsuming and errorprone. AI group control acts like autopilot, analyzing weather, occupancy, and equipment status to optimize modes in real time. For example, it reduces chiller output during offpeak hours (e.g., mornings in malls) and ramps up during peak demand—all with zero human intervention, cutting costs effortlessly.

Ⅱ Construction: Where Details Make or Break Efficiency

"Highefficiency construction isn’t an expense—it’s an investment!"

● Lower bills: Precision engineering cuts system resistance → 15% pump energy savings.

● Fewer headaches: Millimeterperfect installation extends equipment life → 30% lower annual maintenance costs.

● Futureproof: BIM + digital handover → halves future retrofit/expansion costs.

Pipes: "Gentle Bends Win Races"

Sharp 90° elbow joints increase water resistance, forcing pumps to work harder. Using 45° arcs and optimized layouts reduces drag, while smooth welds and lowresistance valves keep flow efficient.

Insulation: "A Warm Jacket for Pipes"

Poor insulation lets cold air escape, wasting millions in electricity yearly. Highquality insulation—like a thick down coat—seals every valve and flange, trapping cold where it belongs.

Installation: "Precision Matters"

Misaligned pumps or poorly placed cooling towers can slash efficiency by 10%. BIM prefabrication and rigorous commissioning ensure everything fits perfectly—the "rite of passage" for highefficiency rooms.

ⅢOperation: AI + Preventive Maintenance = LongTerm Savings

Many cooling rooms grow inefficient over time due to poor upkeep. Here’s how to avoid that:

AI "Night Shift"

AI group control monitors equipment 24/7, predicting issues (e.g., bearing wear) before they cause breakdowns. It also generates energy reports, highlighting waste and inefficiencies.

"SPA Days" for Equipment

Dirty cooling towers or clogged filters tank performance. Regular cleaning—like a refreshing spa—restores peak efficiency.

ⅣPerformance Metrics: How Much Can You Save?

Judge a cooling room’s efficiency by these 3 key metrics:

● Annual Energy Efficiency Ratio (AEER):

Highefficiency rooms: AEER > 5.0 (vs. 3.0–4.0 for traditional ones).

More cooling per kWh = big savings.

● Energy Savings:

Cuts 30–50% of electricity use vs. standard rooms—enough to buy a BMW yearly!

● Failure Rate:

AIdriven maintenance reduces failures by 70%, slashing downtime and repair costs.

Conclusion: The "Invisible Money Printer"

Ready to turn your cooling room into a savings engine? Contact Infraswin Energy now!